Difference between revisions of "Hondata Tuning Guide"

| Line 51: | Line 51: | ||

If you do decrease the sensitivity, you should only do so until you're just barely seeing noise. If you completely eliminate noise, there's a good chance you won't be picking up knock as early either, making the knock retard strategy significantly less effective. | If you do decrease the sensitivity, you should only do so until you're just barely seeing noise. If you completely eliminate noise, there's a good chance you won't be picking up knock as early either, making the knock retard strategy significantly less effective. | ||

| + | |||

=== Identifying real knock === | === Identifying real knock === | ||

Revision as of 01:20, 14 October 2020

This guide covers the specifics of tuning a 2017+ Honda Civic Type R from start to finish using a Hondata FlashPro. It is meant for those that are already familiar with EFI tuning and the Hondata interface. There are many videos and courses online about both of those subjects, so many general topics won't be covered in depth here in order to focus on techniques specifically for the FK8. If you do not understand the fundamentals of EFI tuning, you should not attempt to follow this guide blindly. An FK8 ECU is great for someone to learn tuning on, but you must understand electronic fuel injection first.

This guide is meant to be read from start to finish. General information regarding tuning a Type R can be found on the Tuning article.

Disclaimer

You are fully responsible when using the information in this guide. This is meant to be purely informational on a platform where there is very little info, and some things may not be correct or even safe. New techniques and problems with old techniques are constantly being found.

Core Concepts

To tune a Civic Type R, you must first become intimately familiar with a few concepts that affect nearly every aspect of the tuning process.

Bosch ECU

The 10th generation Civic Type R does not have a Honda ECU, instead featuring a Bosch MED v17.9.3. The techniques for tuning them are significantly different.

Luckily, Hondata has managed to make their FlashPro tuning platform and most of the advanced features like traction control work with the Bosch ECU so existing Hondata tuners do not have to learn an entirely new software. The only other Honda to feature this ECU was the 2015+ European FK2 Civic Type R.

All ignition values are locked to steps of 0.75 degrees.

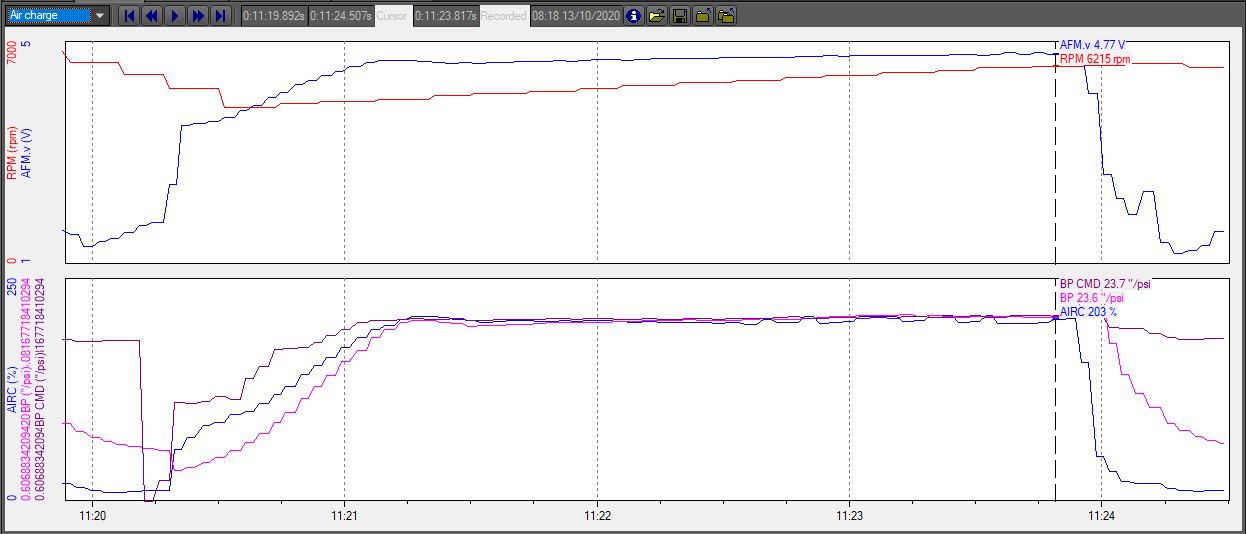

Air charge

The Bosch ECU uses a significantly more accurate load index for targeting fueling, ignition, and cam angles. It calculates how much air is actually inside the cylinder rather than the overall flow through the intake and engine. It is a ratio expressed as a percentage of the physical mass/amount of air in the cylinders at bottom dead center compared to how much the cylinders would hold at the currently measured atmospheric pressure. Anything above 100% and the engine is under boost, anything below 100% is vacuum.

The actual mass of air throughout any turbocharged application's intake and cylinders varies wildly, particularly during sudden throttle changes. Things like VTEC can significantly change the amount of air in the cylinder for each stroke despite the overall flow and calculated engine load not instantly changing, and since VTEC crossover generally happens around peak torque it's vital for this measurement to be correct at that immediate time. By having an immediate measurement of the mass of air in the cylinders instead of just what is passing by the MAF sensor or how much pressure the manifold is under, the Civic Type R is able to target a theoretical amount of torque reliably under all environmental and operating conditions with significantly less room for error, regardless of what modifications are installed. This ECU was designed by Bosch to easily adjust to any engine or intake setup and we get the benefits of that.

Air charge is very similar to both SAE absolute and relative engine load and uses the same sensors, but the calculations are time-domain rather than instantaneous and are also significantly more complex. The actual formula is not known or standardized like SAE engine load, but we have a guess. The ECU will first track how much air has flowed past the MAF sensor into the charge pipes, determining how much pressure that airflow is maintaining before the throttle plate using the boost pressure sensor. It will also watch the manifold pressure after the throttle plate to determine how much of the air is entering from the charge pipes, leaving out of intake manifold and thus (hopefully) going into the cylinders. Because the ECU is sampling the MAP sensor in high resolution in order to properly measure the pressure drops as the intake valves open, datalogs will usually show it fluctuating under load by 1 to 2 psi.

This tightly controlled calculation is the reason why the all-too-common vent-to-atmosphere blowoff valves (or any other way for the air to escape unmeasured i.e. boost leaks) or 'performance chips' that intercept the sensors can potentially reduce the reliability and safety of the engine, despite everything looking normal mostly in datalogs.

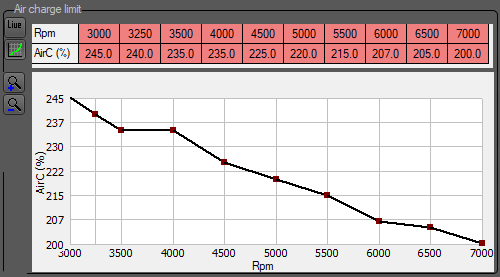

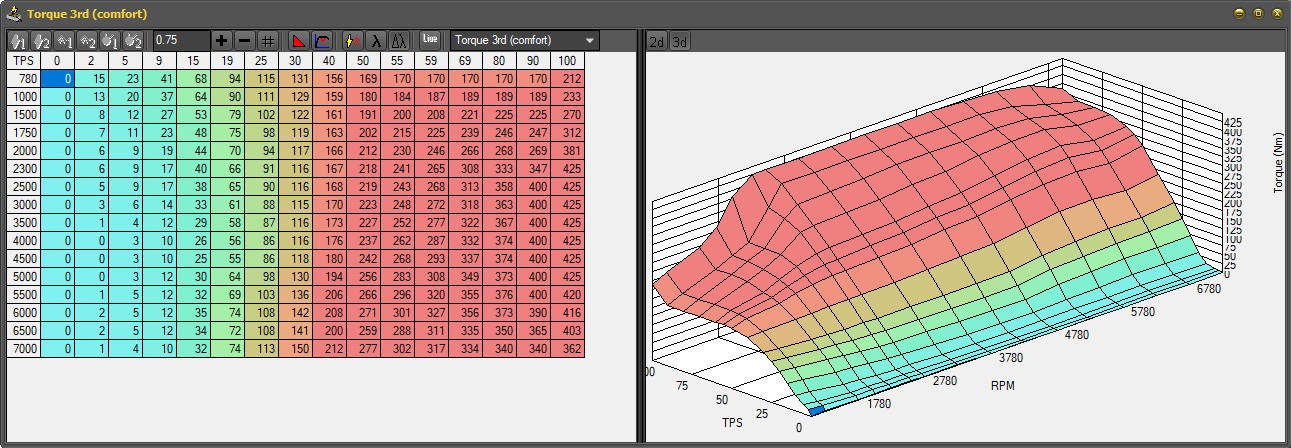

Torque targeting

Everything begins with the throttle pedal position and current RPM corresponding to a certain amount of requested torque, with an individual table for each gear and drive mode totaling 18 torque request tables.

The ECU will calculate how much air charge and ignition advance is required to achieve the requested torque, up to the limits defined in various tables. The air charge will determine boost pressure command, and then from that the throttle plate position and wastegate position. You do not directly tune boost pressure on an FK8, but you can effectively tune in the same manner as boost by gear with more consistent power results.

While other Honda platforms are compared by their targeted PSI, it is more appropriate to compare an FK8's capability and tune by the targeted air charge.

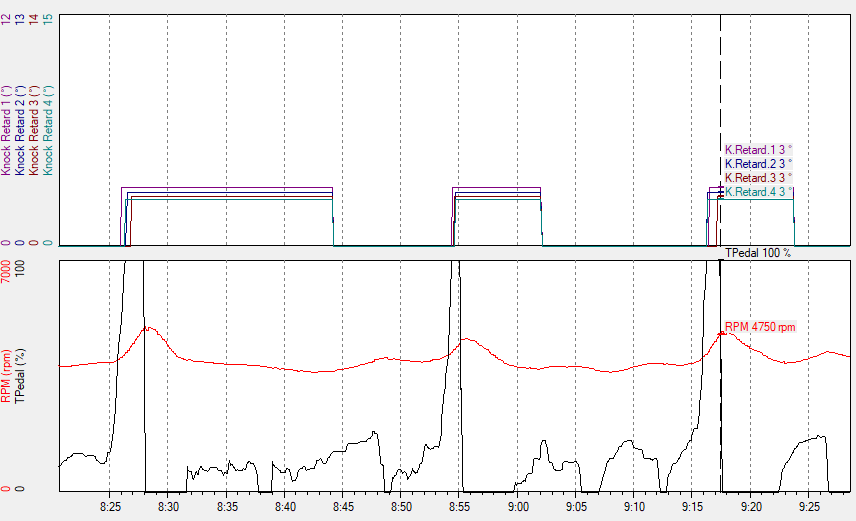

Monitoring and controlling knock

Unlike other Hondas, the Type R does not use a traditional knock control strategy that learns a fuel's octane level over time. Instead, when the knock sensor picks up noise outside of a certain window, ignition retard is gradually applied to the knocking cylinder and will remain until throttle input is reset. This system has no memory and will consistently allow knock, albeit rapidly eliminating it once detected.

Due to the nature of this knock strategy, the factory knock sensor calibration is also extremely sensitive and will regularly pick up noise and register more false knock than most platforms. However, because the ignition retard is incremental it has very little effect on power from these tiny false knock events and the sensitivity should generally be left alone unless there is a significant amount of noise from a part such as an exhaust.

This is important to know, because it means that improperly tuning ignition or using low quality fuel can result in consistent knock that never goes away and the driver would never know unless they reviewed their logs.

Calibrating knock retard

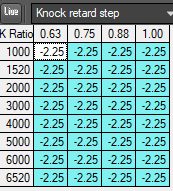

There are two parameters to the knock retard system: step and window. The step is how much ignition retard is applied in each 'step' the knock retard system takes expressed as a negative number of degrees, and is -2.25 degrees from factory. Generally speaking, you should set the step to -3 when you are working with uncertain fuel or testing new ignition values, and -0.75 to -1.50 if you are certain the fuel is consistently high quality and no knock normally occurs.

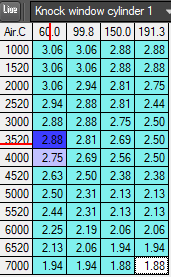

The knock windows can be increased in order to decrease the sensitivity of the knock retard system, but extreme caution should be exercised in doing so. Generally speaking, increasing the values by 10 to 20 percent is sufficient for even the noisiest of FK8s. There is a separate table for each cylinder, allowing fine tuning for difficult cylinders.

If you do decrease the sensitivity, you should only do so until you're just barely seeing noise. If you completely eliminate noise, there's a good chance you won't be picking up knock as early either, making the knock retard strategy significantly less effective.

Identifying real knock

Due to the regular presence of noise and false knock, it's important to know what real knock typically looks like on an FK8 and when it can be passed off as noise.

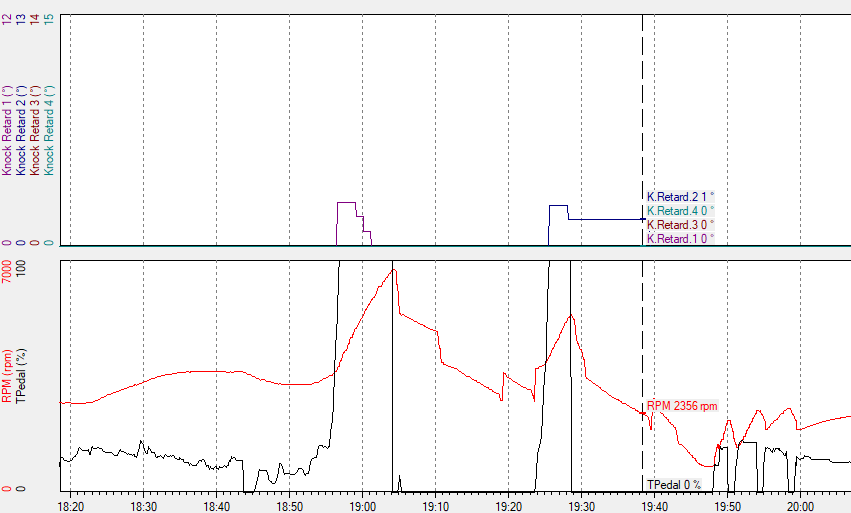

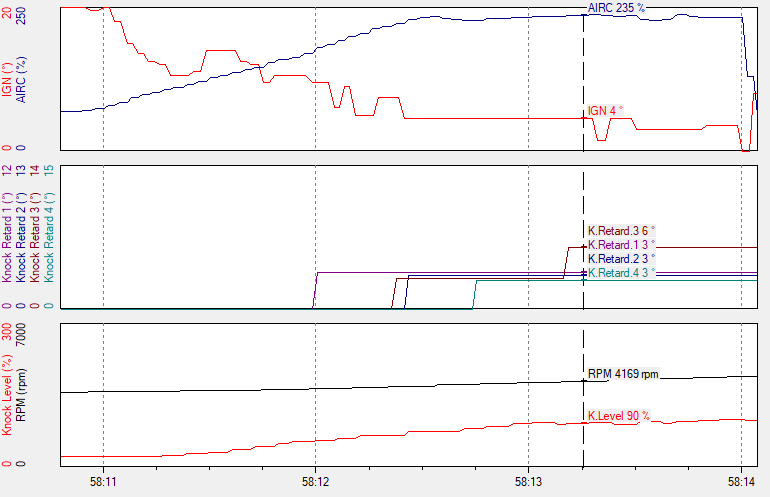

Knock can be most easily identified by a gradual increase across three to four cylinders, the so called 'rainbow knock'. Seeing more than three steps in two cylinders or more than four steps in a single cylinder is also cause for investigation.

However, seeing lots of little single cylinder one-step spikes across a datalog is not a concern, especially if it occurs right when the throttle is applied and not during a WOT pull near redline.